Demand and purchase planning

Helmes has partnered TeliaSonera’s Estonian affiliate for many years in developing a demand-driven supply chain management information system. In close cooperation with the client, the system was developed in order to minimize lost sales with the optimum amount of goods in stock at any time.

Satisfaction with the solution as well as a positive cooperation experience provided Helmes with the opportunity to present an offer in TeliaSonera’s central procurement of a Common Demand and Purchase

Planning Tool (CDPPT) which would:

- maintain maximum availability of consumer electronics;

- reduce man-hours spent fulfilling it; and

- develop an automated monitoring module so that errors in logistics processes would be discovered as soon as possible.

Competing with world-class software providers’ products, Helmes was chosen to develop a custom solution that would precisely reflect TeliaSonera’s innovative supply chain management process.

Compared to its competitors, Helmes offered maximum flexibility and agility, which were considered crucial when providing the shortest time to market in order to reduce the payback period of the investment.

Lars Liljestam, TeliaSonera Project manager

I’m sorry for not telling you more often how happy I am with your work!

Nina Fogelberg, TeliaSonera Project manager

I think it’s great that you’ve been able to deliver in such an effective way. I always talk about our great Estonian supplier that delivers ahead of time with more in the scope! ;)

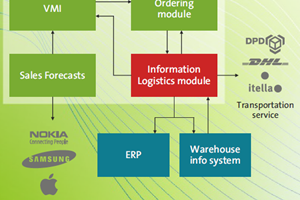

The CDPPT system incorporates the full functionality of a continuous replenishment information system for demand-driven supply chain management. It shares realtime market information with all of the members of the supply chain. Responding to changes in demand flexibly makes it possible to optimise the elements of the logistics mix – stock, storage, packing, transport and communication.

The system is highly configurable, so as to meet the differing needs of each TeliaSonera country. The configuration options are maintained through permission. Each country can, at any time, change its settings and set-up without any excessive need for

software development or support.

As the system is highly business-critical, it has a built-in monitoring module which enables Helmes to detect possible errors (including user interaction that does not follow common patterns) in real time. Most often the problem is solved and reported before the client has even noticed that an error has occurred. The system can help detect the source of the error, including third parties’

information systems, quickly and accurately.

The project’s aim was to implement the system developed in Estonia after customization and localization in seven TeliaSonera countries. A pilot project was carried out in one country. After this, implementation and integration work was carried out in two countries at a time. At the same time, the core of the system was developed and each implemented system was supported and maintained.

Implementation involves integration with almost 30 different information systems – in each country the system has its interfaces with different ERP solutions (e.g. SAP, Scala, Oracle, Oracle 1B, EBS and custom ERP systems), the warehouse, couriers’ systems, the provider’s information systems (such as Nokia, Samsung and Apple) and so on.

Organisation of the project involved, at different times, around 80 different contact people on the client’s side (central and local project contact people), from Helmes and from third parties (transportation, suppliers etc.). Communication during the project was intensive, as is required for development in close cooperation with the client.

Helmes took full responsibility for successful integration rather than just building TeliaSonera’s end of the interfaces. In many cases the third parties needed Helmes’ technical expertise in integration to finalize their interfaces. Communication with third parties was managed by Helmes, saving the time and energy of project managers.

Throughout the project Helmes provided full flexibility in changing any part of it – the countries, the functionalities to be developed, due dates etc. As a project supervisor Helmes took responsibility for indicating delays caused by all parties and managing the process to meet the overall due date.

A well-planned information and product flow provides a competitive advantage in terms of both prices and service levels. CDPPT automates orders and supply chain management in accordance with real-time market needs.

The possibility of errors is minimised by replacing manual labour with automation and closely monitoring each step of the process.

The main benefits

- accurate forecasts and no lost sales:

- no fixing capital in excessive stock while providing the required service level;

- shorter time for goods in stock and less need for storage space;

- optimised work of packers and transportation; and

- automated communication within the supply chain both ways.

Benefits of custom software

- maximum flexibility;

- maximum agility;

- maximum response rate to maintain and support highly business-critical information systems;

- end-to-end responsibility in integration; and

- information system that reflects the fine-tuned logistics processes of a market leader providing a competitive edge

TeliaSonera

Url: www.teliasonera.com

TeliaSonera provides network access and telecommunication services that help people and companies communicate in an easy, efficient and environmentally friendly way.